If you’ve noticed the coating on your Calphalon cookware starting to chip or wear off, you’re not alone.

Calphalon’s anodized coating, known for its durability and non-stick properties, can sometimes show signs of wear over time.

But why does this happen, and what steps can you take to address it?

In this blog post, we’ll delve into the reasons behind the coating wearing off and offer some practical tips on maintaining and prolonging your cookware’s life. Let’s dive in.

Reasons Behind Anodized Coating Wearing Off

There are various reasons that cause anodized coating to wear off; here are a few:

Improper Care

Improper care and maintenance of anodized cookware, especially the practice of putting it in the dishwasher against the manufacturer’s recommendations, can significantly impact its longevity and performance.

Anodized cookware is treated with an electrochemical process that hardens the surface of aluminum, making it non-reactive, durable, and resistant to corrosion.

However, this protective layer can be compromised by exposure to harsh conditions, such as those found in dishwashers.

Dishwasher detergents typically contain strong chemicals and abrasives designed to remove tough stains and grease from dishes.

When anodized cookware is subjected to these aggressive detergents and the high-temperature environment of a dishwasher, the protective anodized layer may start to degrade.

The combination of heat, water pressure, and chemicals can gradually wear off the anodized coating, leading to discoloration, loss of non-stick properties, and, eventually, corrosion or pitting on the surface.

Hand washing anodized cookware, on the other hand, allows for more control over the cleaning process.

Using a mild dish soap and a soft sponge or cloth ensures gentler treatment of the cookware surface.

Avoiding harsh scrubbing pads or abrasive cleaners prevents unnecessary wear on the anodized layer.

Additionally, hand drying the cookware immediately after washing helps to prevent water spots and corrosion that can occur when it’s left to air dry.

High Heat Exposure

Anodized coatings are commonly used to enhance the durability and corrosion resistance of various metal products, including cookware.

However, when these items are consistently exposed to high temperatures, it can compromise the integrity of the anodized coating.

The breakdown of the anodized coating under high heat conditions is primarily due to the altered chemical and physical properties of the coating material.

Anodization involves an electrochemical process that creates a protective oxide layer on the surface of the metal, typically aluminum.

This layer is robust and provides resistance against corrosion and wear under normal usage conditions.

Yet, extreme heat can induce several detrimental effects on this protective layer. At elevated temperatures, the anodized coating may undergo thermal degradation.

The increased heat causes the oxide layer to lose some of its protective properties, resulting in a breakdown of the molecular structure.

This breakdown leads to discoloration, wherein the coating might change color due to the chemical alterations occurring within its structure.

Moreover, prolonged exposure to high temperatures, especially at maximum heat settings or placing the cookware under a broiler, exacerbates these issues.

The excessive heat intensifies the rate of chemical reactions within the anodized coating, hastening its degradation.

Areas consistently exposed to extreme heat may experience accelerated wear and tear, leading to localized loss of the protective coating.

This loss compromises the overall integrity of the cookware, potentially exposing the underlying metal to corrosion and reducing its lifespan.

Preventing or mitigating this issue involves prudent use and care of the anodized cookware.

Avoiding prolonged exposure to high temperatures, especially at maximum heat settings, is crucial.

Opting for lower to medium heat settings during cooking can help preserve the integrity of the anodized coating.

Additionally, refraining from using the cookware under broilers or subjecting it to extreme temperature differentials, such as transferring directly from a hot stove to a cold surface, can also mitigate the degradation of the coating.

Abrasive Cleaning Materials

Abrasive cleaning materials, although effective at removing tough stains and grime, can inadvertently cause damage to surfaces, especially those with delicate coatings like anodized surfaces.

Understanding the nature of abrasives and their impact on these surfaces is crucial to preserving the integrity and longevity of the coating.

Anodized surfaces undergo a process where a protective layer is formed, enhancing the metal’s resistance to corrosion, wear, and scratches.

This layer is integral to the surface’s durability. However, the use of abrasive cleaning tools disrupts this protective layer by creating microscopic scratches.

Even though these scratches might seem negligible initially, with repetitive use, they accumulate and compromise the integrity of the anodized coating.

Abrasive cleaners often contain gritty particles or chemicals that aid in scrubbing. While efficiently removing stubborn stains, they can be too harsh for anodized surfaces.

These cleaners essentially exacerbate the damage caused by abrasive tools, intensifying the erosion of the protective coating.

The consequence of this erosion is twofold. First, it weakens the anodized layer, making it more susceptible to further damage from environmental factors, such as moisture or chemicals.

Second, it reduces the surface’s aesthetic appeal as the scratches accumulate and become more visible over time.

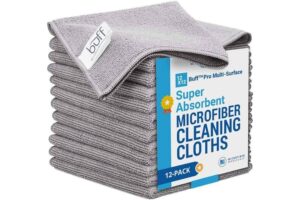

To maintain anodized surfaces effectively while avoiding damage from abrasives, it’s vital to employ gentler cleaning methods.

Using non-abrasive cleaning solutions that are specifically formulated for anodized surfaces can help preserve the protective layer without compromising its integrity.

Additionally, opting for soft cleaning tools like microfiber cloths or soft-bristled brushes minimizes the risk of scratching while effectively removing dirt and grime.

Metal Utensils

Thanks to its electrochemically treated surface, anodized cookware is known for its durability and non-stick properties.

However, using metal utensils with anodized cookware can compromise these advantages.

The hardness of the anodized coating varies depending on the process used during manufacturing, but even the toughest anodized surfaces can succumb to damage from metal utensils.

The issue primarily arises due to the difference in hardness between the anodized layer and the metal utensils.

Most metals used in utensils—like stainless steel or even certain types of spatulas or spoons—are harder than the anodized layer.

When these harder utensils come into contact with the anodized surface, they can cause abrasions, scratches, or even gouges.

These scratches might seem insignificant initially, especially if they’re small. However, they weaken the integrity of the anodized coating.

Continuous use of metal utensils exacerbates this, gradually wearing off the coating in areas that have been repeatedly scratched or abraded.

This compromises the non-stick properties and can expose the underlying metal, potentially leading to corrosion and affecting the lifespan of the cookware.

Chemical Exposure

Exposure to certain chemicals or highly acidic/alkaline substances poses a significant threat to anodized coatings.

While these coatings are generally resilient, prolonged contact with acidic substances like vinegar or strong cleaning solutions can compromise the protective layer.

These substances gradually erode the coating, causing it to wear off or discolor.

The chemical reactions weaken the protective layer’s integrity, rendering it less effective in safeguarding the metal underneath.

This degradation is a gradual process, often manifesting as a loss of luster or changes in coloration.

Frequent Use and Age

Regular use and the passage of time contribute to the natural wearing off of anodized coatings.

The continuous application of heat, exposure to various foods, washing, and handling gradually diminishes the protective layer.

As the cookware undergoes these routine activities, the anodized layer thins, becoming more vulnerable to damage.

Over time, this thinning effect, coupled with the aging process of the cookware itself, accelerates the wearing off of the coating.

This aging process involves a gradual breakdown of the anodized layer, which can lead to changes in its appearance and reduced effectiveness in protecting the underlying metal.

Improper Storage

Improper storage of anodized cookware is a common reason behind the wearing off of its coating.

Anodized cookware is designed to have a durable and corrosion-resistant layer, but improper storage practices can compromise this protective layer over time.

When cookware is stacked or stored without adequate protection between pieces, friction occurs between the surfaces.

This constant rubbing and contact create abrasions, particularly at the points where the surfaces touch each other.

Stacking or storing anodized cookware without protective layers allows direct contact between surfaces.

The anodized layer, though durable, isn’t impervious to constant friction, leading to wear.

Lack of cushioning or separation materials between pieces causes metal-on-metal contact, accelerating wear on the anodized coating.

Storing cookware in contact with acidic or reactive materials can also contribute to coating degradation due to chemical reactions.

Preventive Measures and Maintenance Tips

When the anodized coating on Calphalon cookware starts to wear off, there are a few steps you can take:

Stop Using Damaged Pieces

If the wear has resulted in rough or damaged areas on the cooking surface, it’s best to stop using that particular piece of cookware.

Continued use might compromise the quality of your cooking and potentially affect food safety.

Use Wooden Utensils

To prevent this damage, it’s advisable to use utensils made of materials softer than the anodized layer, such as silicone, plastic, wood, or bamboo.

These materials are less likely to cause scratches or abrasions on the anodized surface.

Additionally, choosing utensils with smooth edges can further minimize the risk of damaging the coating.

Contact Calphalon

Ensure you reach out to Calphalon’s customer service. They might have specific recommendations or warranty coverage for such cases.

Depending on the warranty and the nature of the wear, they might offer replacement or repair options.

Consider Recoating Services

Some companies offer services to recoat anodized cookware. It involves stripping the old coating and applying a new anodized layer.

However, this might not be a standard service and could involve additional costs.

Dispose of or Repurpose

If the wear is extensive and the cookware is no longer usable for cooking, consider repurposing it for non-cooking uses (such as storing non-food items) or disposing of it properly according to local waste disposal guidelines.

Use Protective Layers

Insert protective layers like cloth or silicone pads between each piece of cookware to create a barrier against direct contact.

Then, stack cookware thoughtfully, ensuring that heavier items are at the bottom and using separators to prevent scratching and abrasions.

Store anodized cookware away from reactive substances or chemicals that could compromise the coating’s integrity.

Adhere to the manufacturer’s instructions for proper care and storage of anodized cookware.

These guidelines often include specific recommendations for maintenance and storage to prolong the coating’s life.

Conclusion

In conclusion, discovering that the Calphalon anodized coating is coming off can be frustrating, but understanding its reasons and taking appropriate steps can help address the issue.

Whether it’s due to wear and tear, improper use, or manufacturing defects, being informed about the potential causes empowers you to make informed decisions.